product center

High quality high performance excellent service

Search productSearch post

High quality high performance excellent service

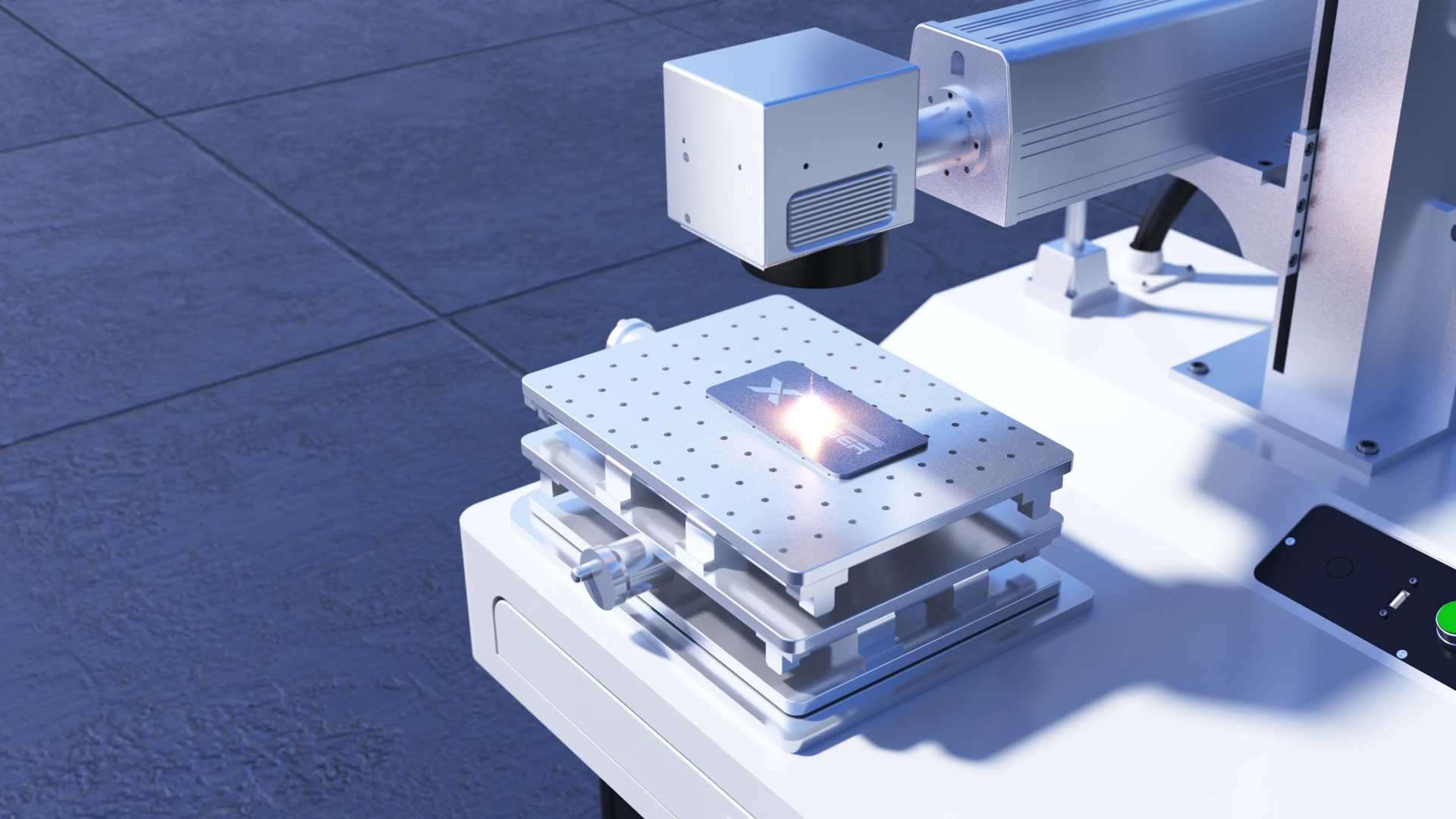

Efficient and stable lasermarking platform

Efficient and stable lasermarking platform

With the same stable platform, you can choose from three laser sources:

fiber optic for various metals;

CO2 for non-metals; and ultraviolet for ultra-precise cold processing.

These three laser options provide you with a stable, efficient, and precise marking solution tailored to your materials.

With the same stable platform, you can choose from three laser sources,fiber optic for various metals CO2 for non-metals; and ultraviolet for ultra-precise cold processing.These three laser options provide you with a stable, efficient, and precise marking solution tailored to your materials.

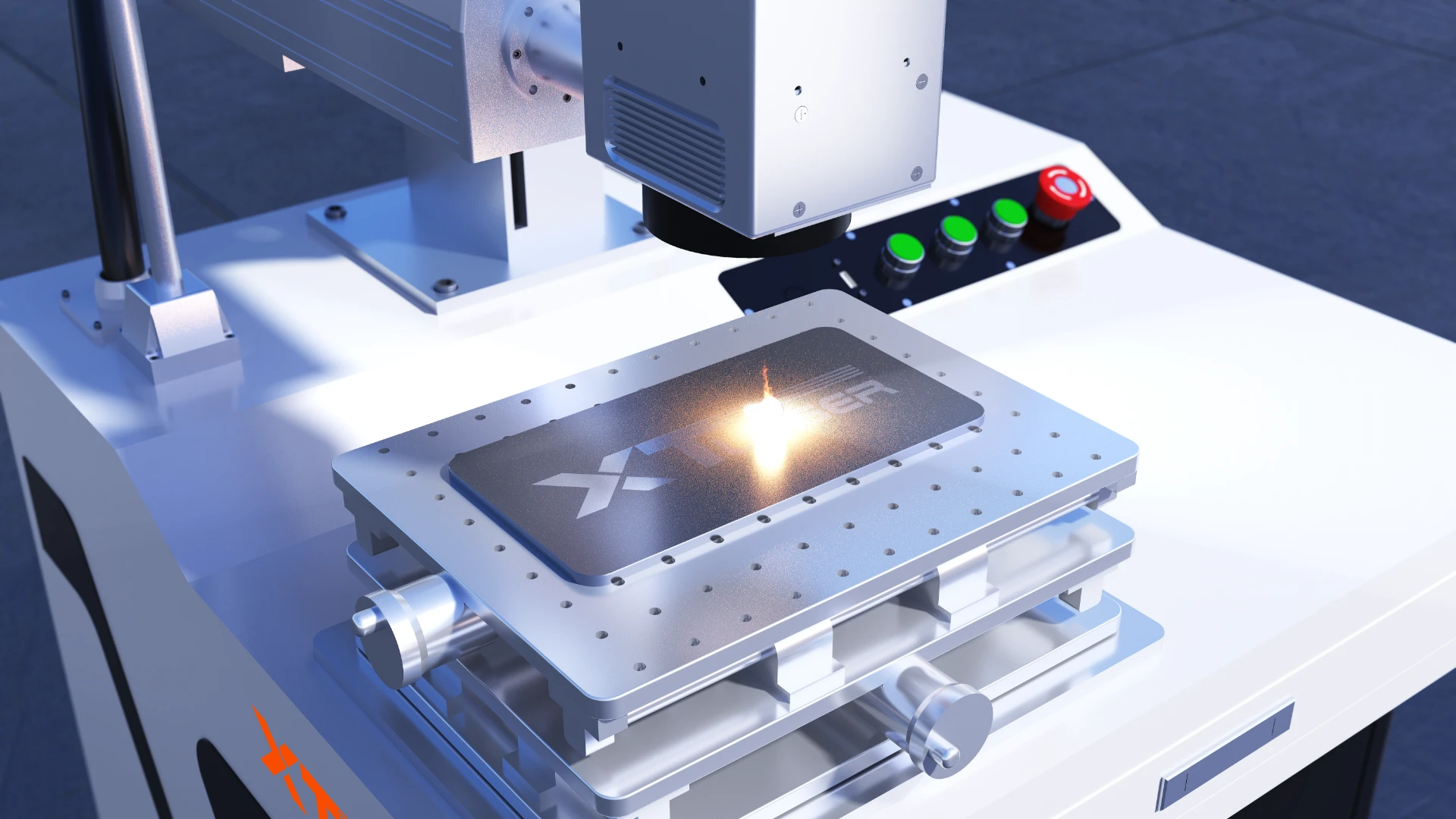

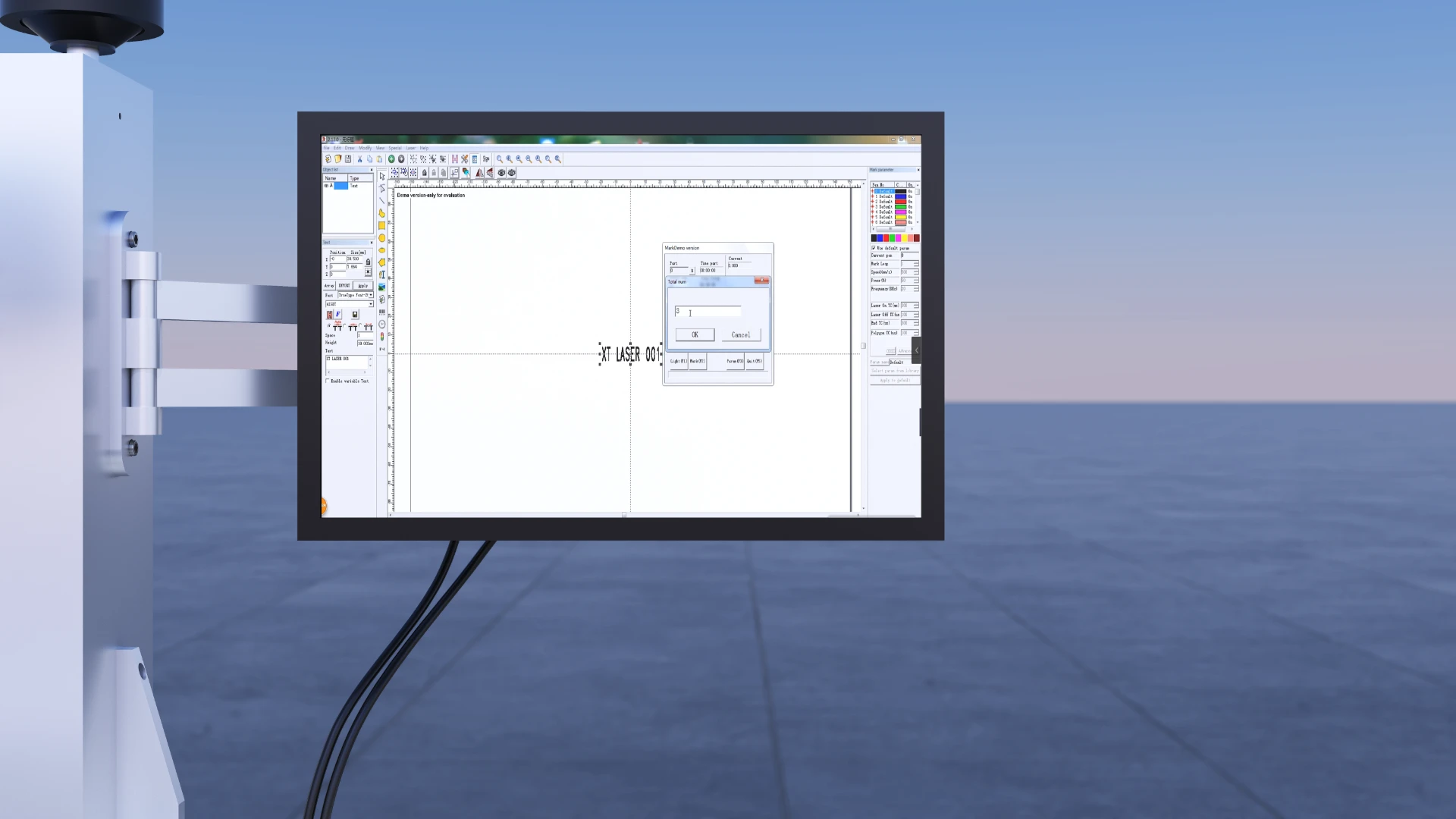

The marking process is incredibly fast, far surpassing traditional techniques, greatly improving production efficiency.

The marking precision is exquisite, with clear and sharp strokes, easily achieving a delicate texture comparable to printing quality.

The marking process is incredibly fast, far surpassing traditional techniques, greatly improving production efficiency.The marking precision is exquisite, with clear and sharp strokes, easily achieving a delicate texture comparable to printing quality.

With a service life of up to 100,000 hours and a continuous service life of 5-10 years,

the equipment consumes far less energy than traditional processing equipment,

making it the preferred solution for achieving green and low-carbon production.

With a service life of up to 100,000 hours and a continuous service life of 5-10 years,the equipment consumes far less energy than traditional processing equipment, making it the preferred solution for achieving green and low-carbon production.

Adopting a highly integrated all-in-one design, the structure is compact and robust,

and can be put into stable and continuous production operation as soon as it is powered on,

which greatly ensures attendance rate and production efficiency.

Adopting a highly integrated all-in-one design, the structure is compact and robust,and can be put into stable and continuous production operation as soon as it is powered on,which greatly ensures attendance rate and production efficiency.which greatly ensures attendance rate and production efficiency.

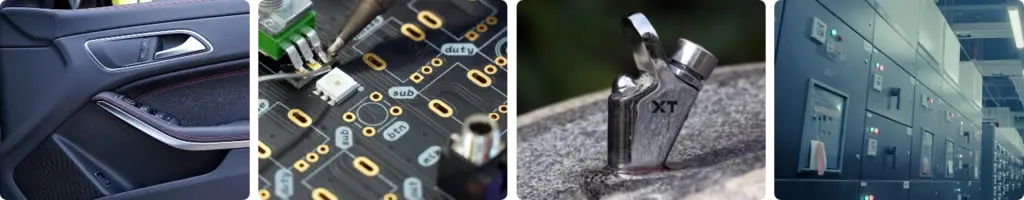

Application industries

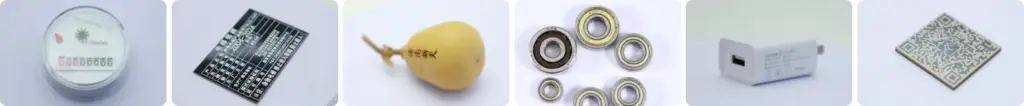

Electronic components, integrated circuits (ICs), electrical appliances, mobile communications, hardware products, tool accessories, precision instruments

Sample display

待提供

待提供

For more questions, please contact us.

Fiber laser cutting machines can cut most metal materials, including stainless steel, carbon steel, aluminum, copper, alloy steel, galvanized sheet, titanium, etc. They are widely used in sheet metal processing, kitchen utensils, aerospace, metal cabinets, automotive parts, construction and other industries.

Laser cutting technology has significant comprehensive advantages over traditional cutting methods (such as flame cutting, plasma cutting, waterjet cutting).

High precision laser cutting, narrow kerf width, smooth and burr-free, small heat-affected zone, no need for secondary grinding and polishing.

Non-contact processing, no mechanical stress, avoiding tool wear or material deformation.

Fiber laser cutting machines require professional laser cutting control software and CAM software to process design files and generate cutting paths, such as LightBurn, AutoCA, etc., and are compatible with DXF, SVG, AI (Adobe Illustrator), EPS, DWG, PDF, PLT, etc.

The laser power of the laser cutter depends on the cutting material and thickness. If you don’t know how to choose the right power for your device, please contact us.

Clean or replace the optics (focusing mirror, reflector) and nozzle regularly to avoid contamination affecting the cutting quality.

Check the operation status of the cooling system (water-cooled or air-cooled) to ensure that the water temperature and flow rate are normal to prevent the laser from overheating.

Clean the debris of the guide rail, screw and other transmission parts and lubricate them regularly to ensure the precision of movement; check the filtering device of the dust removal system and clean the soot residue in time.

XT LASER’s sheet metal laser cutting machine is equipped with a visual operation interface and a detailed operation manual, so even if you are a novice, you can quickly get started. If you are a beginner, it is recommended to read the safety guide before use, or contact our professional technicians online.

The lead time is usually 4 to 6 weeks, depending on the type of equipment and the specific needs of the customer. We will provide a detailed delivery schedule at the time of order confirmation and maintain communication during production and transportation to ensure on-time delivery.

We use cookies to optimize our website , analyze traffic, and provide you with more relevant service information. Some of these cookies are strictly necessary for the site's basic functions.

You can choose whether to accept cookies used for analytics and ad performance optimization.

You can learn more in our Privacy Policy