product center

High quality high performance excellent service

Search productSearch post

High quality high performance excellent service

Environmental protection and precision, small parts expertise

Product Introduction

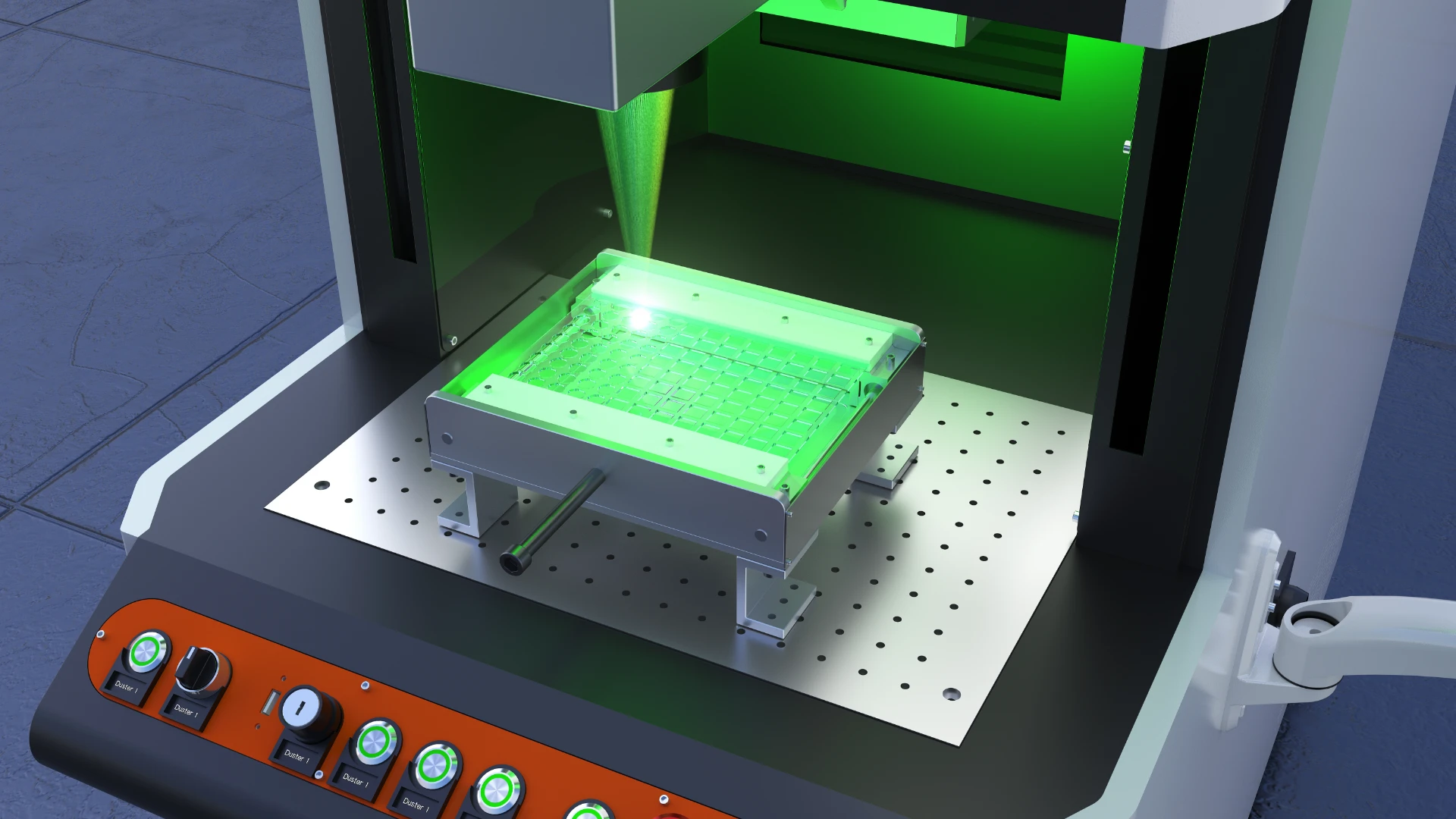

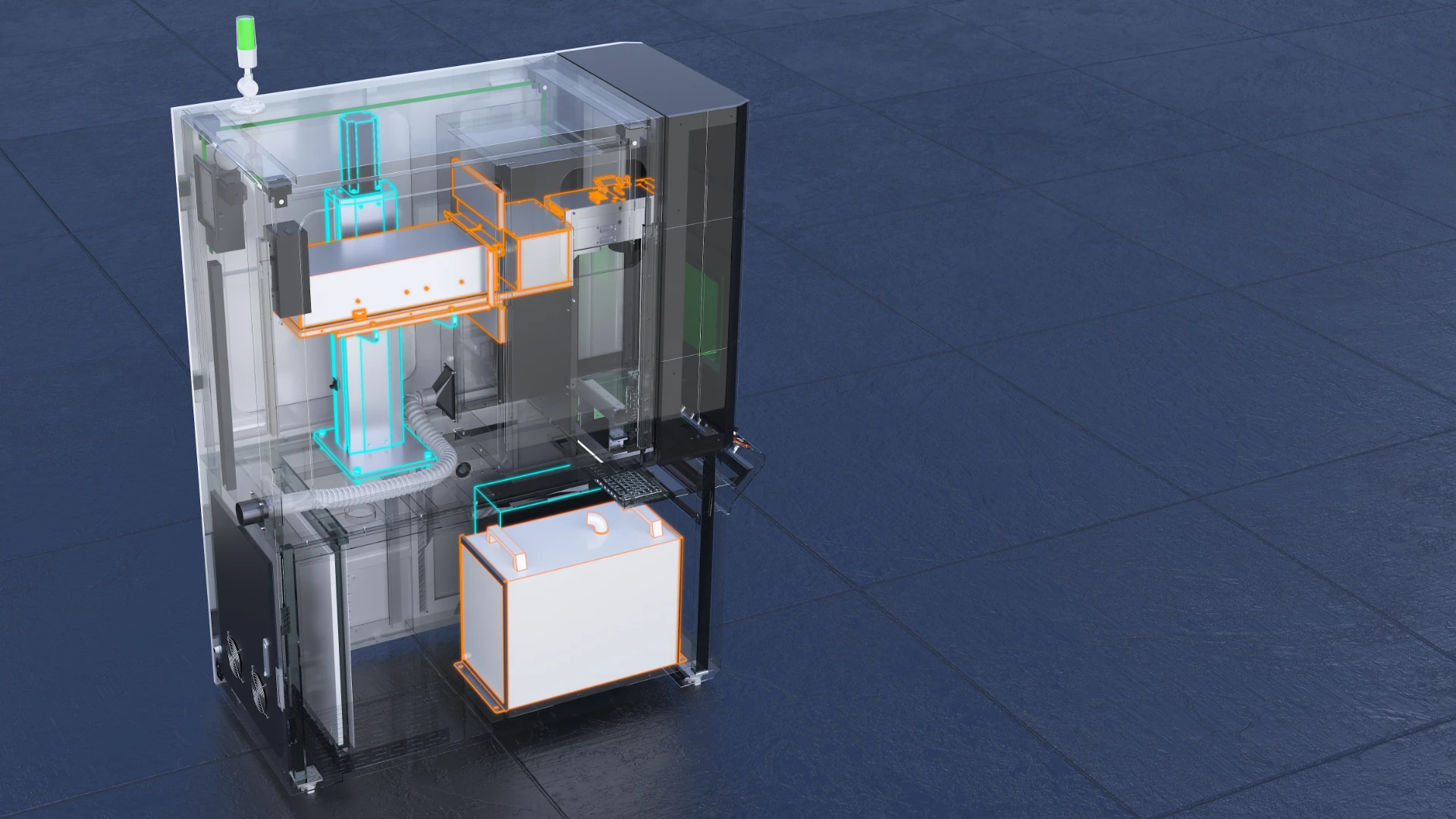

Green light glass punching machine adopts green light nanosecond laser and galvanometer drilling processing method.It uses a single pulse to act on thebase material point by point.The laser focus is installed in a predetermined designed path to quickly scan and move on the glass to remove the glass material.

Laser processing subverts tradition

Focus on precision processing of square holes and round holes in small-format and small-size glass,

high workpiece absorption rate,small edge collapse,more delicate processing quality

Focus on precision processing of square holes and round holes in small-format and small-size glass, high workpiece absorption rate,small edge collapse,more delicate processing quality

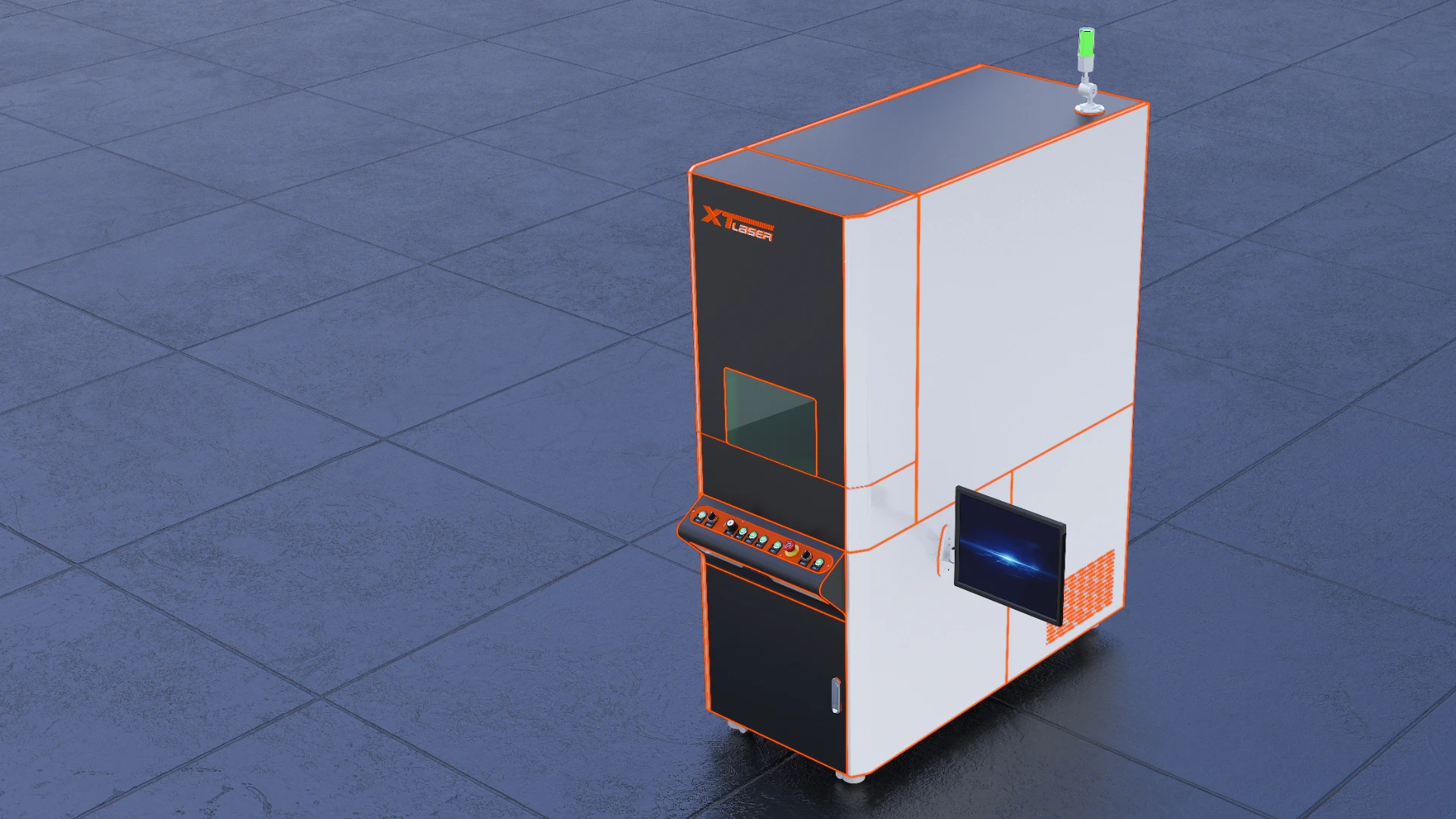

Fully enclosed cover design isolates laser radiation

and ensures safe operation

Fully enclosed cover design isolates laser radiation and ensures safe operation

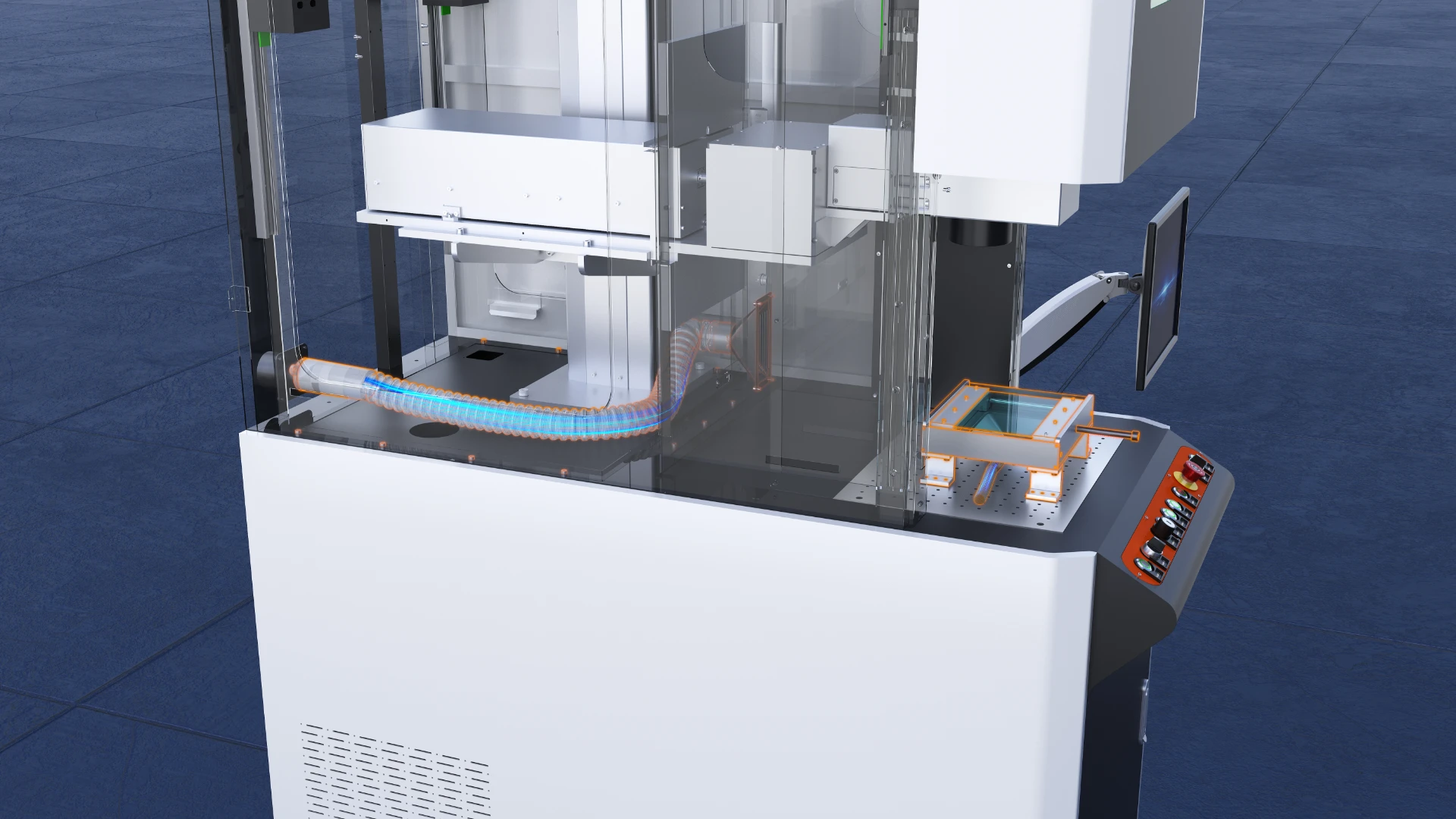

Negative pressure vacuuming in the working area can maximize the cleaning of glass powder.

At the same time,auxiliary vacuuming inside the whole machine can further purify the

working environment and ensure safe use.

Negative pressure vacuuming in the working area can maximize the cleaning of glass powder.At the same time,auxiliary vacuuming inside the whole machine can further purify the working environment and ensure safe use.

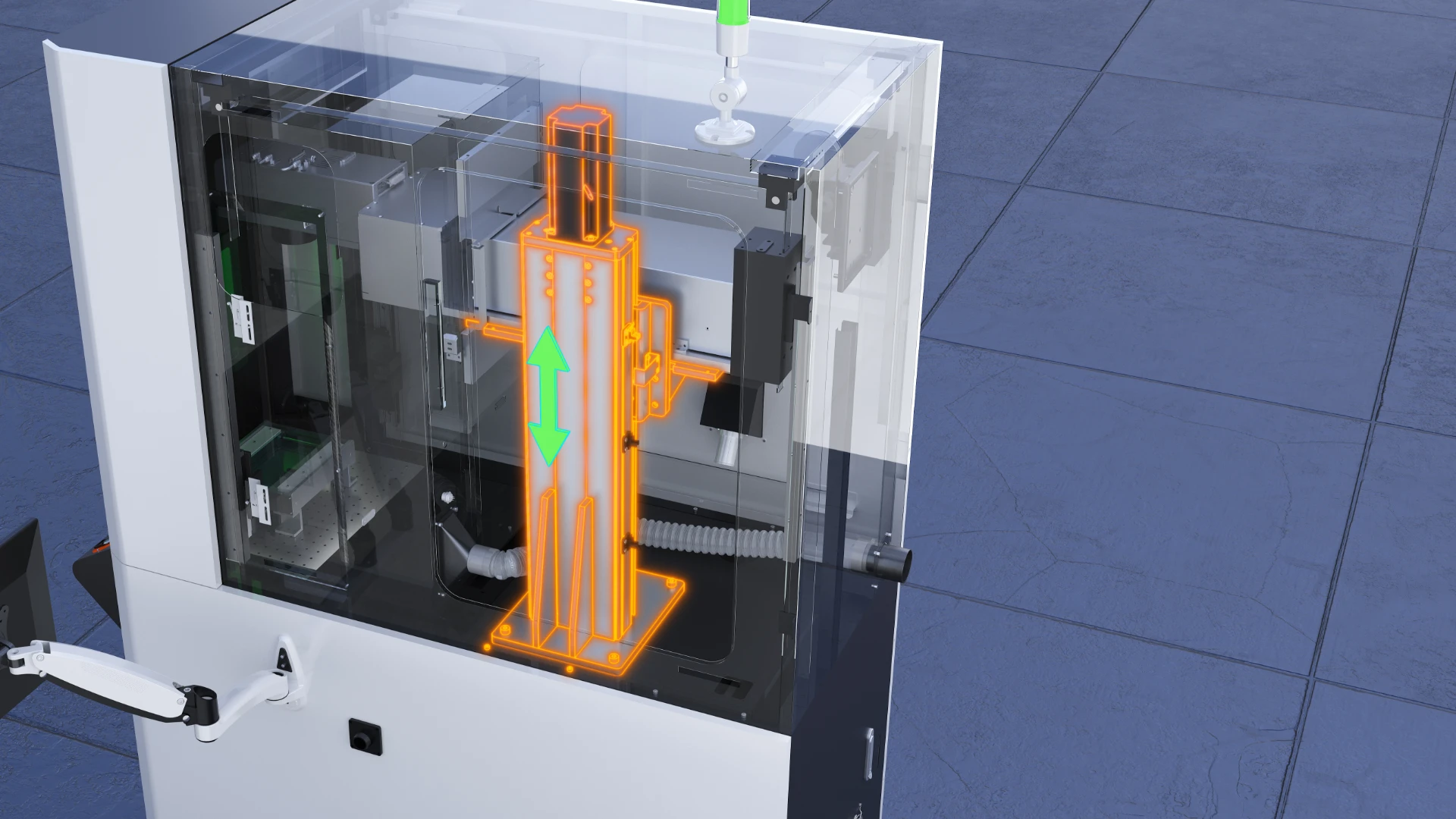

Fully automatic servo adjustment,

efficient and accurate,

fast and convenient

Fully automatic servo adjustment,Fully automatic servo adjustment,fast and convenient

The whole machine is integrated,integrating the laser,

optical path components,chiller,computer and electronic

control components.The whole machine has no external

components,which greatly improves the space utilization.

The whole machine is integrated,integrating the laser,optical path components,chiller,computer and electronic control components.The whole machine has no external components,which greatly improves the space utilization.

Flexible rotation at a large angle user-friendly and convenient control

Flexible rotation at a large angle user-friendly and convenient control

Intuitive operation interface and intelligent software, can be quickly mastered with

zero basic knowledge,supports import of multiple file formats,direct reading

of PLT/DXF and other formats without conversion.

Intuitive operation interface and intelligent software, can be quickly mastered with zero basic knowledge,supports import of multiple file formats,direct reading of PLT/DXF and other formats without conversion.

Application industries

Glass drilling is commonly used in various types of industrial substrates,display panels

civil glass, decoration,sanitary ware,photovoltaics and display cover plates in the electronics industry.

Sample display

待提供

待提供

For more questions, please contact us.

Fiber laser cutting machines can cut most metal materials, including stainless steel, carbon steel, aluminum, copper, alloy steel, galvanized sheet, titanium, etc. They are widely used in sheet metal processing, kitchen utensils, aerospace, metal cabinets, automotive parts, construction and other industries.

Laser cutting technology has significant comprehensive advantages over traditional cutting methods (such as flame cutting, plasma cutting, waterjet cutting).

High precision laser cutting, narrow kerf width, smooth and burr-free, small heat-affected zone, no need for secondary grinding and polishing.

Non-contact processing, no mechanical stress, avoiding tool wear or material deformation.

Fiber laser cutting machines require professional laser cutting control software and CAM software to process design files and generate cutting paths, such as LightBurn, AutoCA, etc., and are compatible with DXF, SVG, AI (Adobe Illustrator), EPS, DWG, PDF, PLT, etc.

The laser power of the laser cutter depends on the cutting material and thickness. If you don’t know how to choose the right power for your device, please contact us.

Clean or replace the optics (focusing mirror, reflector) and nozzle regularly to avoid contamination affecting the cutting quality.

Check the operation status of the cooling system (water-cooled or air-cooled) to ensure that the water temperature and flow rate are normal to prevent the laser from overheating.

Clean the debris of the guide rail, screw and other transmission parts and lubricate them regularly to ensure the precision of movement; check the filtering device of the dust removal system and clean the soot residue in time.

XT LASER’s sheet metal laser cutting machine is equipped with a visual operation interface and a detailed operation manual, so even if you are a novice, you can quickly get started. If you are a beginner, it is recommended to read the safety guide before use, or contact our professional technicians online.

The lead time is usually 4 to 6 weeks, depending on the type of equipment and the specific needs of the customer. We will provide a detailed delivery schedule at the time of order confirmation and maintain communication during production and transportation to ensure on-time delivery.

We use cookies to optimize our website , analyze traffic, and provide you with more relevant service information. Some of these cookies are strictly necessary for the site's basic functions.

You can choose whether to accept cookies used for analytics and ad performance optimization.

You can learn more in our Privacy Policy