product center

High quality high performance excellent service

Search productSearch post

High quality high performance excellent service

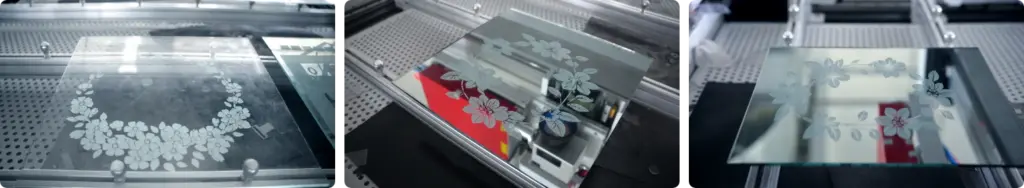

The working principle of laser-brushed glass is to use a high-energy laser beam to instantly generate high temperatures on the glass surface. Through physical processes such as melting, vaporization, micro-explosion, and rapid quenching, a densely distributed microscopic uneven structure is formed. These structures cause strong scattering of incident light, thus producing a visually uniform matte frosted effect while maintaining the integrity and light transmittance of the glass.

Breakthrough advantages of laser grinding machines

It supports large-format processing up to 1300x2500mm, meeting the mass production needs of large workpieces.

It supports large-format processing up to 1300x2500mm, meeting the mass production needs of large workpieces.

Precise positioning enables micron-level processing accuracy, resulting in the delicate rendering of complex patterns.

Precise positioning enables micron-level processing accuracy, resulting in the delicate rendering of complex patterns.

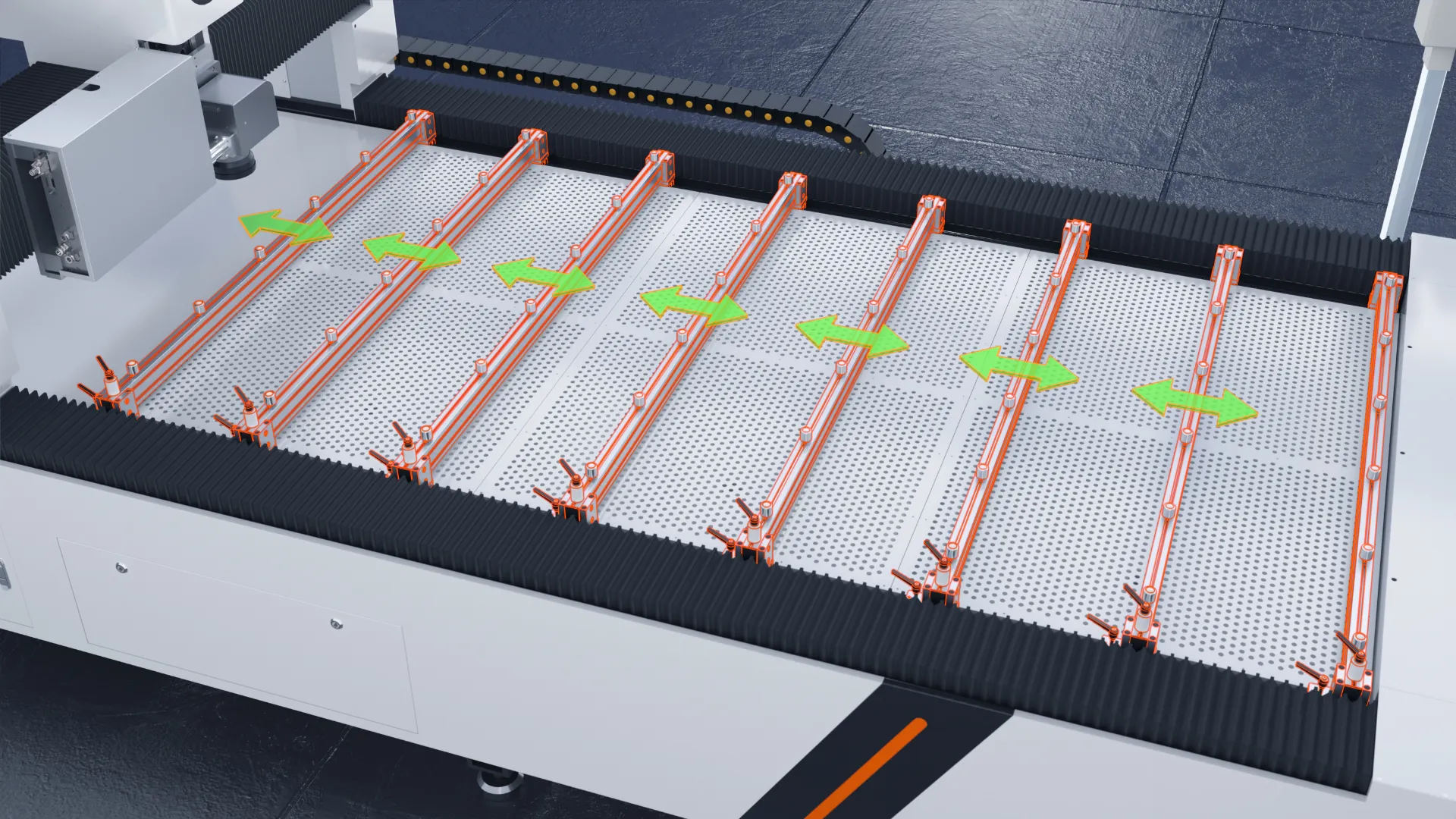

The tabletop size can be freely adjusted according to the material size to match the processing requirements of different glass specifications.

The tabletop size can be freely adjusted according to the material size to match the processing requirements of different glass specifications.

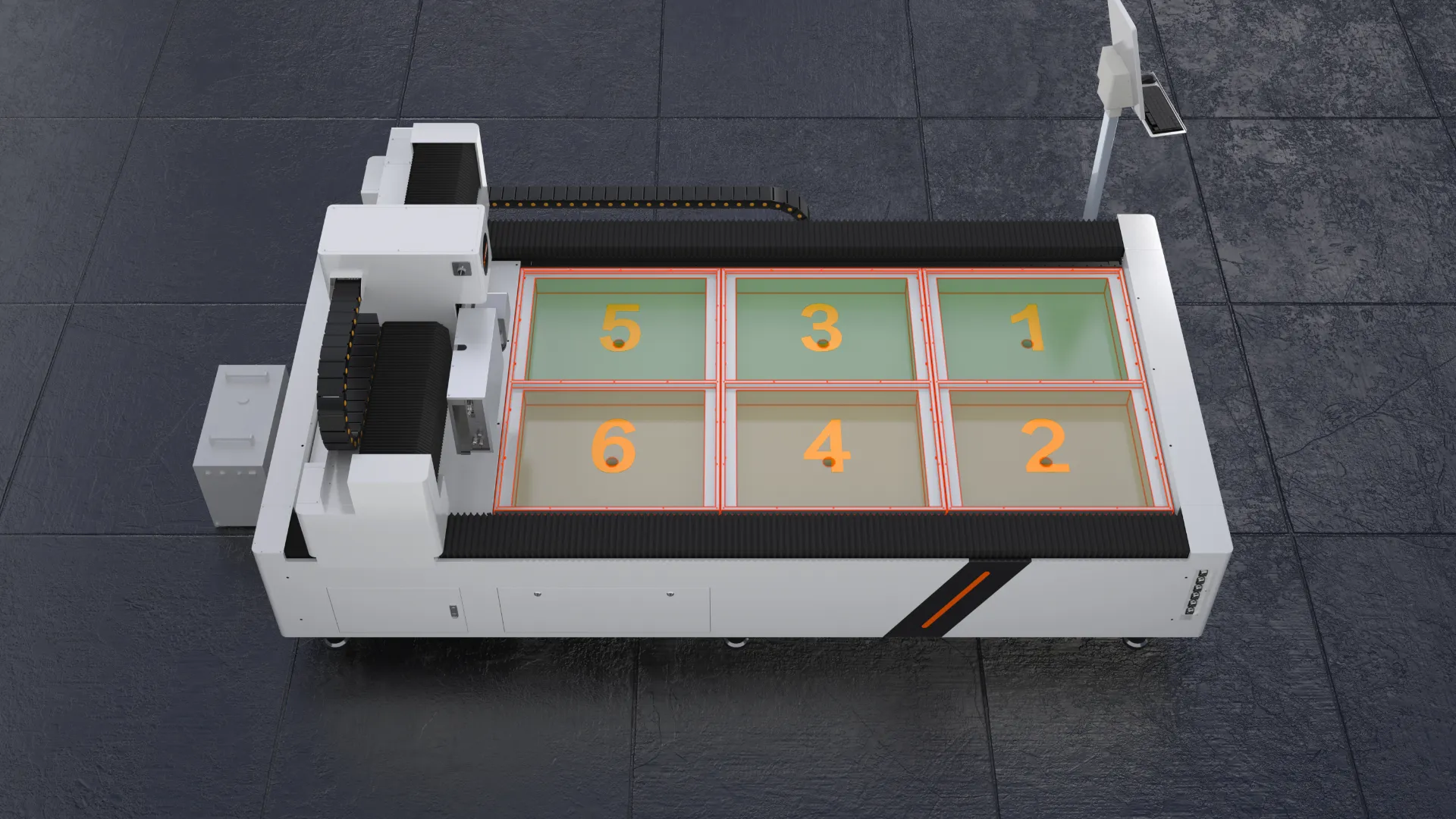

A six-zone independent air control system enables precise dust removal by zone.

A six-zone independent air control system enables precise dust removal by zone.

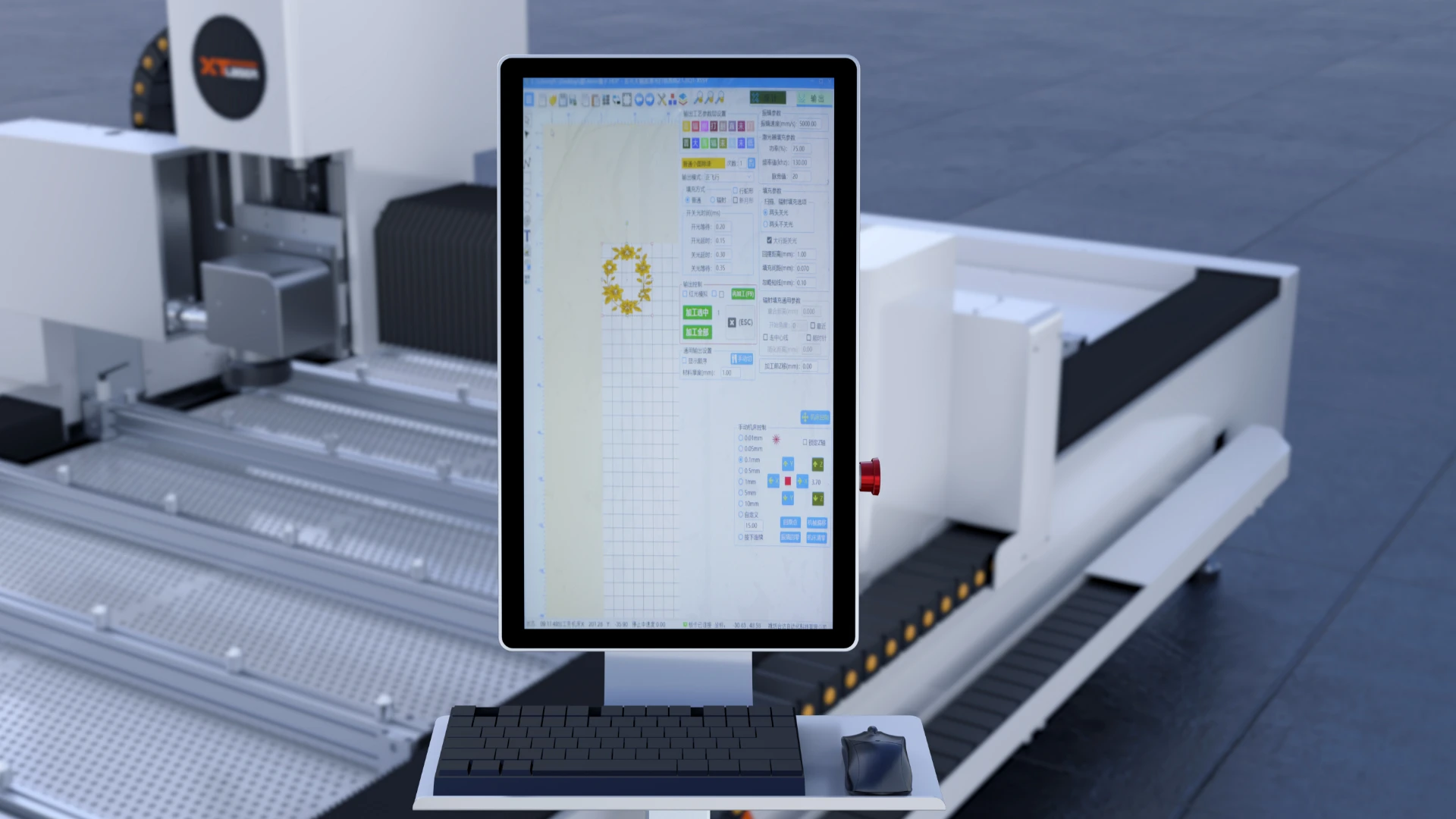

With its intuitive interface and intelligent software, even beginners can quickly master it. It supports importing multiple file formats, including direct reading of PLT/DXF and other formats without conversion.

With its intuitive interface and intelligent software, even beginners can quickly master it. It supports importing multiple file formats, including direct reading of PLT/DXF and other formats without conversion.

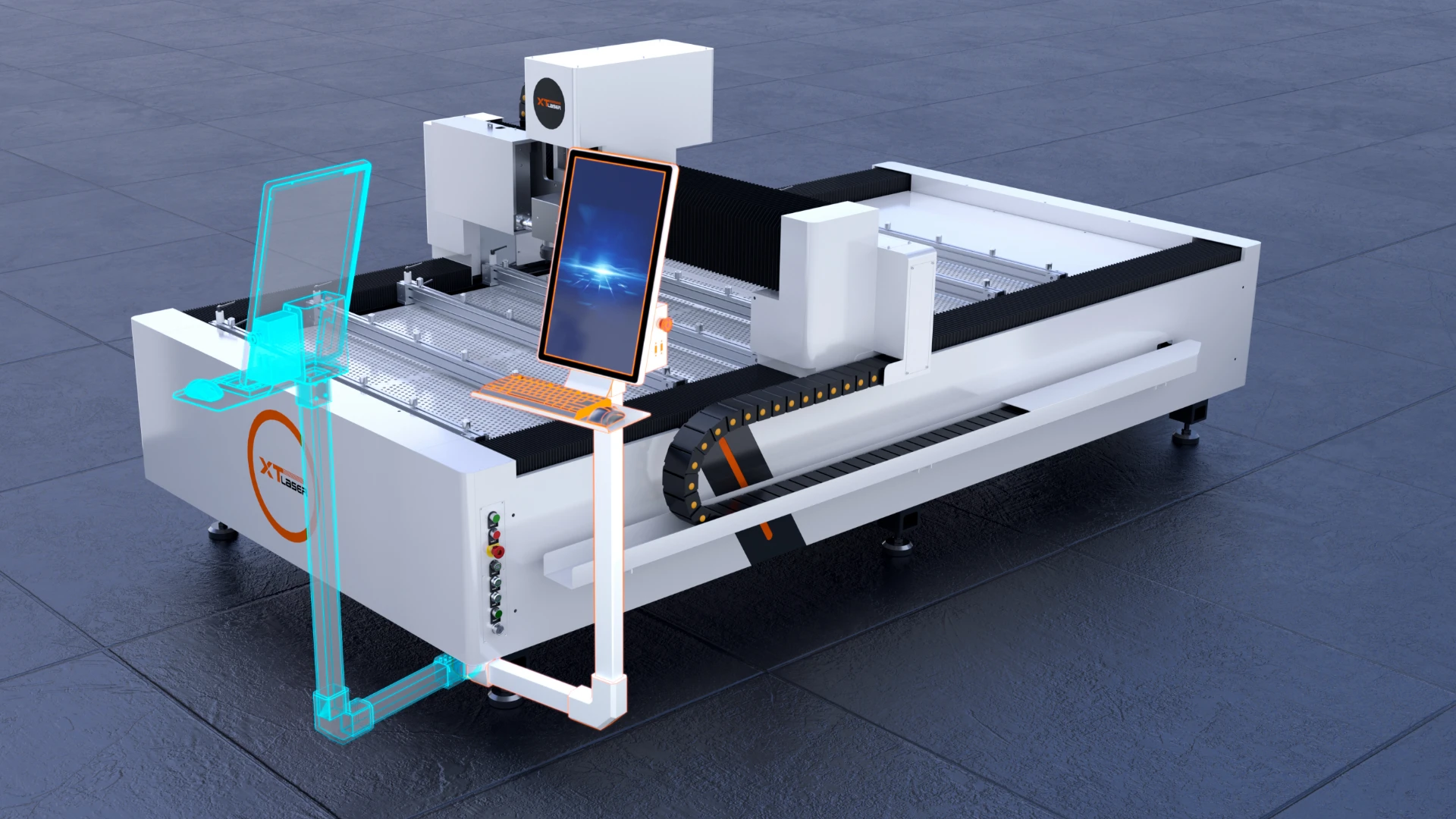

Wide-angle flexible rotation, user-friendly and convenient operation

Wide-angle flexible rotation, user-friendly and convenient operationWide-angle flexible rotation, user-friendly and convenient operation

Application Areas

The glass industry encompasses numerous sub-sectors, including home and smart mirrors, architectural decoration, electronics, automotive, artistic creation and customized products, lighting fixtures, and commercial displays.

Sample display

| 项目 | 大幅面激光玻璃磨砂机 | XTL-GMS1325 |

| 整机总览 | 机柜外形尺寸 | 约3770*2080*1600(H)mm |

| 重量(整机) | 约1150kg | |

| 机械配置 | 床身构造 | 管焊床身 |

| 横梁结构 | 铝型材横梁 | |

| 加工幅面 | 1300*2500mm | |

| 传动机构 | ●导轨+齿条 | |

| 伺服电机及驱动 | ● | |

|

光学配置

|

激光器 | ●红外纳秒激光器 |

| 波段 | 1064nm | |

| 高速振镜 | ● |

For more questions, please contact us.

Fiber laser cutting machines can cut most metal materials, including stainless steel, carbon steel, aluminum, copper, alloy steel, galvanized sheet, titanium, etc. They are widely used in sheet metal processing, kitchen utensils, aerospace, metal cabinets, automotive parts, construction and other industries.

Laser cutting technology has significant comprehensive advantages over traditional cutting methods (such as flame cutting, plasma cutting, waterjet cutting).

High precision laser cutting, narrow kerf width, smooth and burr-free, small heat-affected zone, no need for secondary grinding and polishing.

Non-contact processing, no mechanical stress, avoiding tool wear or material deformation.

Fiber laser cutting machines require professional laser cutting control software and CAM software to process design files and generate cutting paths, such as LightBurn, AutoCA, etc., and are compatible with DXF, SVG, AI (Adobe Illustrator), EPS, DWG, PDF, PLT, etc.

The laser power of the laser cutter depends on the cutting material and thickness. If you don’t know how to choose the right power for your device, please contact us.

Clean or replace the optics (focusing mirror, reflector) and nozzle regularly to avoid contamination affecting the cutting quality.

Check the operation status of the cooling system (water-cooled or air-cooled) to ensure that the water temperature and flow rate are normal to prevent the laser from overheating.

Clean the debris of the guide rail, screw and other transmission parts and lubricate them regularly to ensure the precision of movement; check the filtering device of the dust removal system and clean the soot residue in time.

XT LASER’s sheet metal laser cutting machine is equipped with a visual operation interface and a detailed operation manual, so even if you are a novice, you can quickly get started. If you are a beginner, it is recommended to read the safety guide before use, or contact our professional technicians online.

The lead time is usually 4 to 6 weeks, depending on the type of equipment and the specific needs of the customer. We will provide a detailed delivery schedule at the time of order confirmation and maintain communication during production and transportation to ensure on-time delivery.

We use cookies to optimize our website , analyze traffic, and provide you with more relevant service information. Some of these cookies are strictly necessary for the site's basic functions.

You can choose whether to accept cookies used for analytics and ad performance optimization.

You can learn more in our Privacy Policy